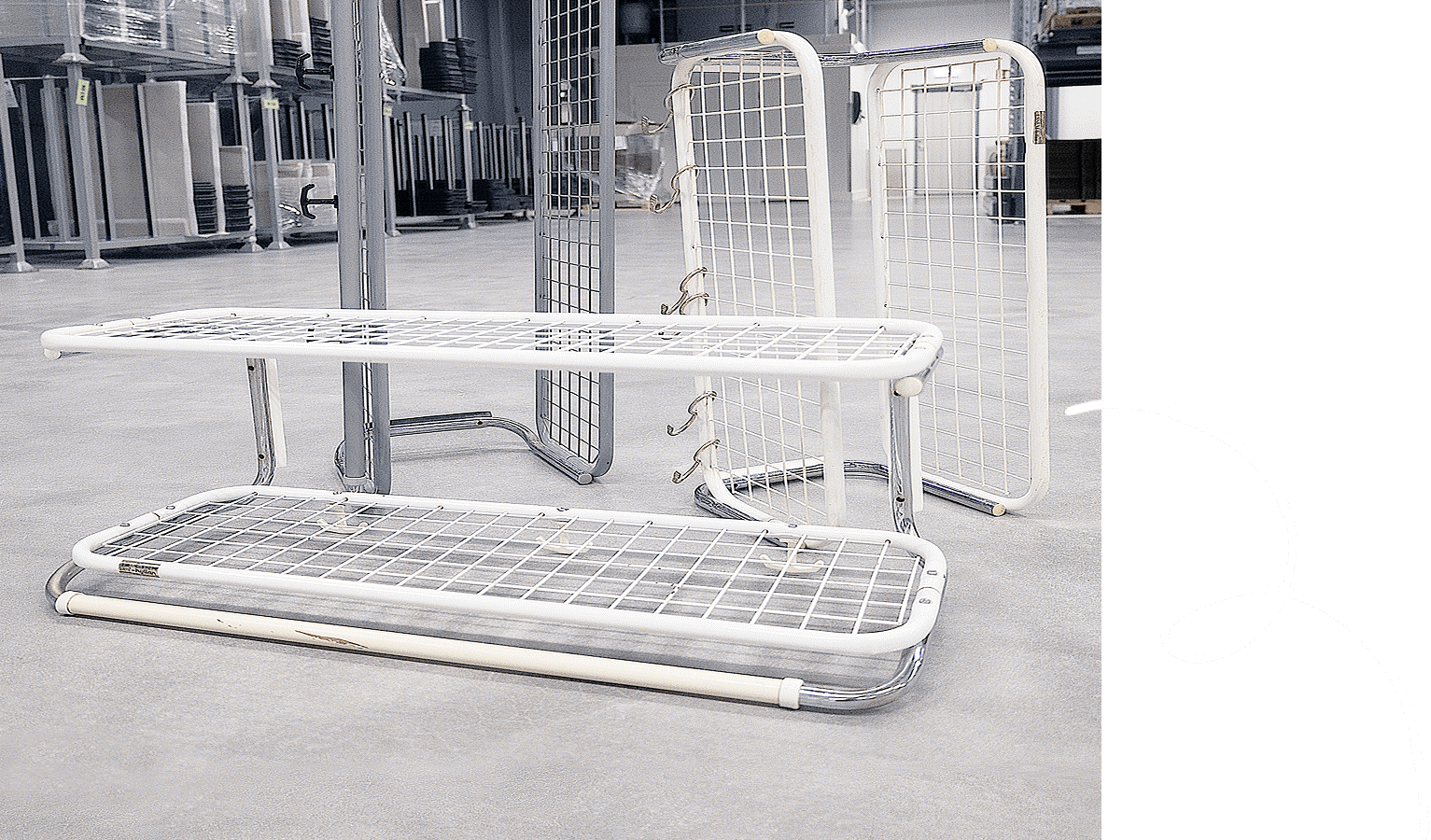

In a recently completed project in

Gothenburg we rescued 25 pieces

of 50-year-old hat racks from being

thrown away and restored them to

new condition.

Old classics brought back to life. Our first major restoration project is here.

At Essem, we believe that the best way to be sustainable is to make products that are made to last. This makes it possible to work with circularity, to reuse, repair and restore to give them an even longer life span.

50-year-old Classic hat racks collected for

renovation. The Classic hat rack was

formerly called the Essem rack and has

been manufactured since the 1950s.

25 Classic hat racks were refurbished to new conditions,

now ready for new customers.

The process – what we did and what we learned

How did we do it – and was it worth it?

This project was a bit of an experiment – we weren’t entirely sure if restoring shelves would be better for the environment or if it would lower CO₂ emissions. But before we get to the results, let’s break down how we disassembled, refurbished, and reassembled the old hat racks to make them as good as new.

The result

A conventionally produced Classic shelf has a total climate impact of 12 kg CO₂ eq. The refurbished Reused Classic? Just 3.4 kg CO₂ eq – a 71% reduction in lifecycle emissions.

What have we learned?

The biggest contributor to CO₂ emissions in the production of hat rack comes from the material, the metal and the steel components. That’s where we see the most potential for future emission reductions.

The biggest contributor to CO₂ emissions in the production of hat rack comes from the material, the metal and the steel components.

Robert Bladh

CEO, Essem Design

Essem and circularity

Hi Magdalena Holm (Sustainability Manager at Essem Design), tell us a bit about the background of the project!

We've had the idea of reuse for a while, so we were of course happy when we were asked to bring the shelves back – not everyone thinks it should be possible to restore them. We've been working on our sustainability profile for a long time, and with a growing trend in this area, it felt perfect to try something like this. It has already provided lessons for the future and the hope is that we will be able to make this an integrated part of our offer.

How did you get started with this reuse project?

We were contacted by a real estate company that they had older Classic shelves in stock after demolition/restoration of apartment buildings. These were going to be disposed of, but we were asked if we wanted them back. The good thing about this is that we both get back material that we can reuse and at the same time can help the real estate company reduce their waste.

What are the benefits of restoring?

Materials make up the majority of our emissions. By sourcing old materials that we can reuse, we can save the environment. We are keen to reduce our environmental footprint and that of our customers.

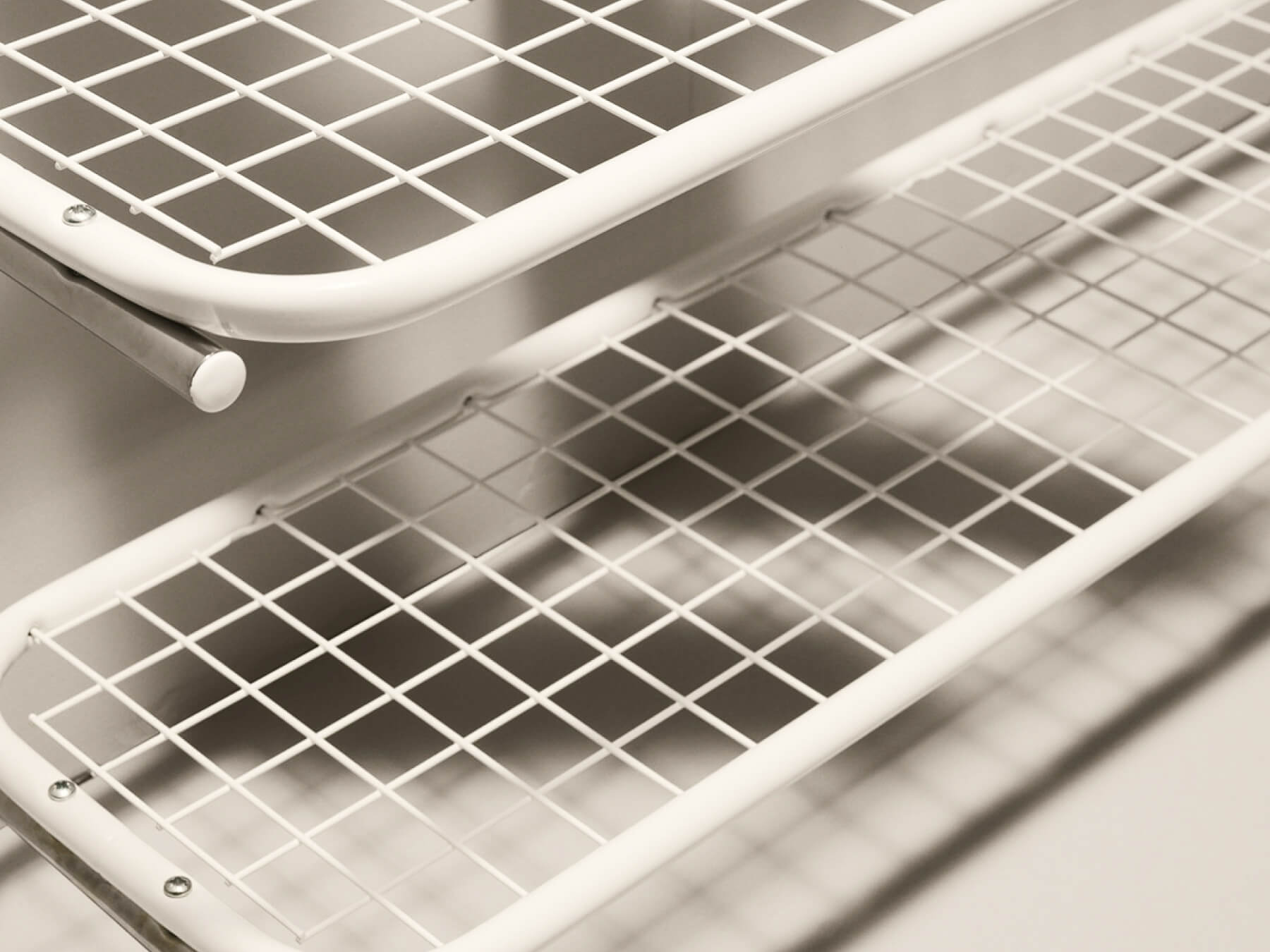

Were there any particular challenges with this project?

The challenge is that it is very resource intensive in terms of man hours and each shelf has different refurbishment needs. Some of the shelves were as old as 50 years and in quite bad condition. We dismantled them, removed old and damaged paint, replaced plastic parts with new ones, and the result was new shelves that will last another 50-60 years.

What will happen to the 25 refurbished hat racks now?

They will be sold to projects and consumers.

Is this something you will be focusing on in the future?

Yes, it is! We see that demand is only going to increase and we want to reduce our environmental footprint and that of our customers. There are already construction projects that have requirements for circularity and reuse, so I think we will only see more of that.

Want to talk about reuse?

Contact us, and we'll talk projects for public spaces, homes, offices,

schools, hotels and more: info@essem.se